Watch How Easy It Is!

The Superstratum Whole Home System is the ultimate mycotoxin cleaning solution. By harnessing the full power of Superstratum products, it reaches every area of your home for the deepest detoxification possible. Easy to use and highly effective, it’s your all-in-one solution to create a healthier living space.

Click play to watch the full tutorial.

The Whole Home Detox:

Your Step-by-Step Guide

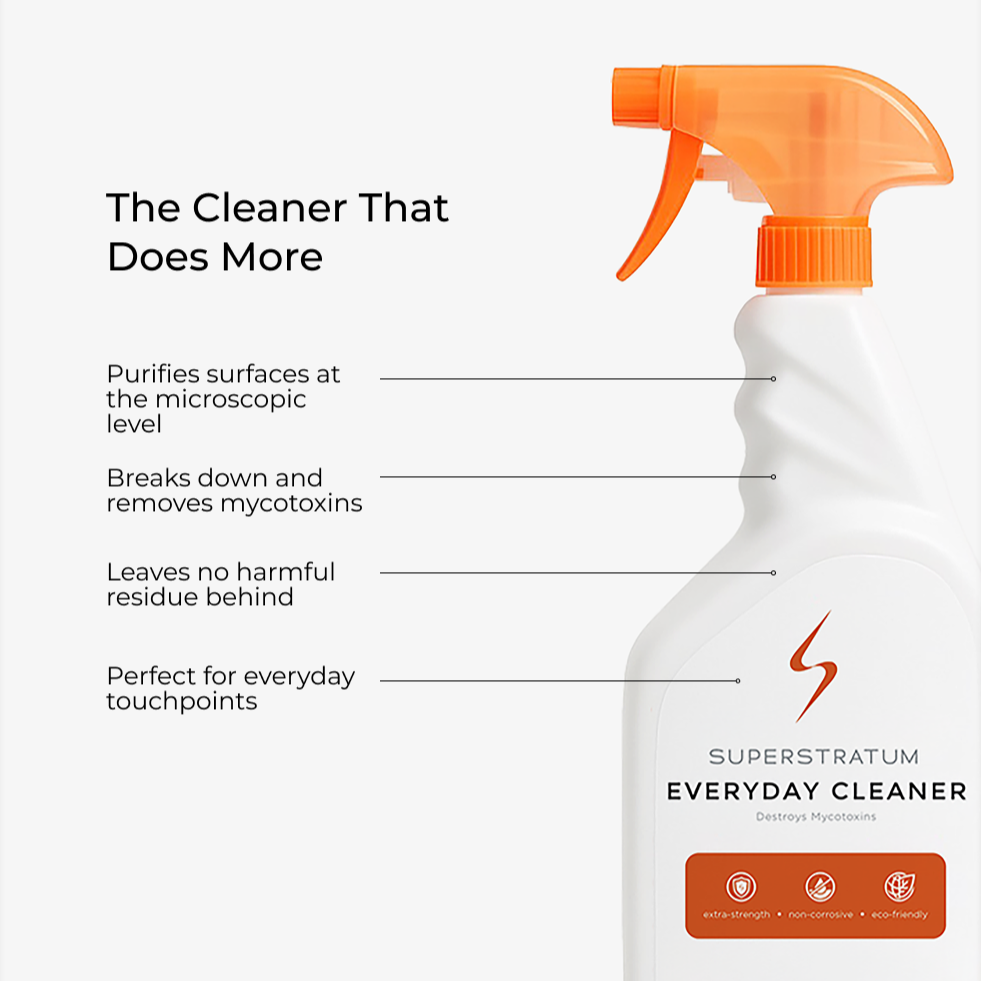

Phase 1: Clean

USE FOR

- Spraying or fogging in buildings to destroy mycotoxins and other inanimate contaminants

QUICK FACTS

- Made with hypotonic-electrolytic hypochlorous acid (HE-HOCl).

- Building Cleaner - 600ppm HE-HOCl

- Everyday Cleaner - 300ppm HE-HOCl

- Tested to remove over 95% of mycotoxins on contact

- 12-month shelf lifeSafe around pets and children

- Non-corrosive

- Neutral pH level

- Ultra Low Volume cold fogger for application

Coverage Area

- 300 square feet per gallon for direct spray application

- 5000 cubic feet per gallon for fogging application

PPE

Not Required

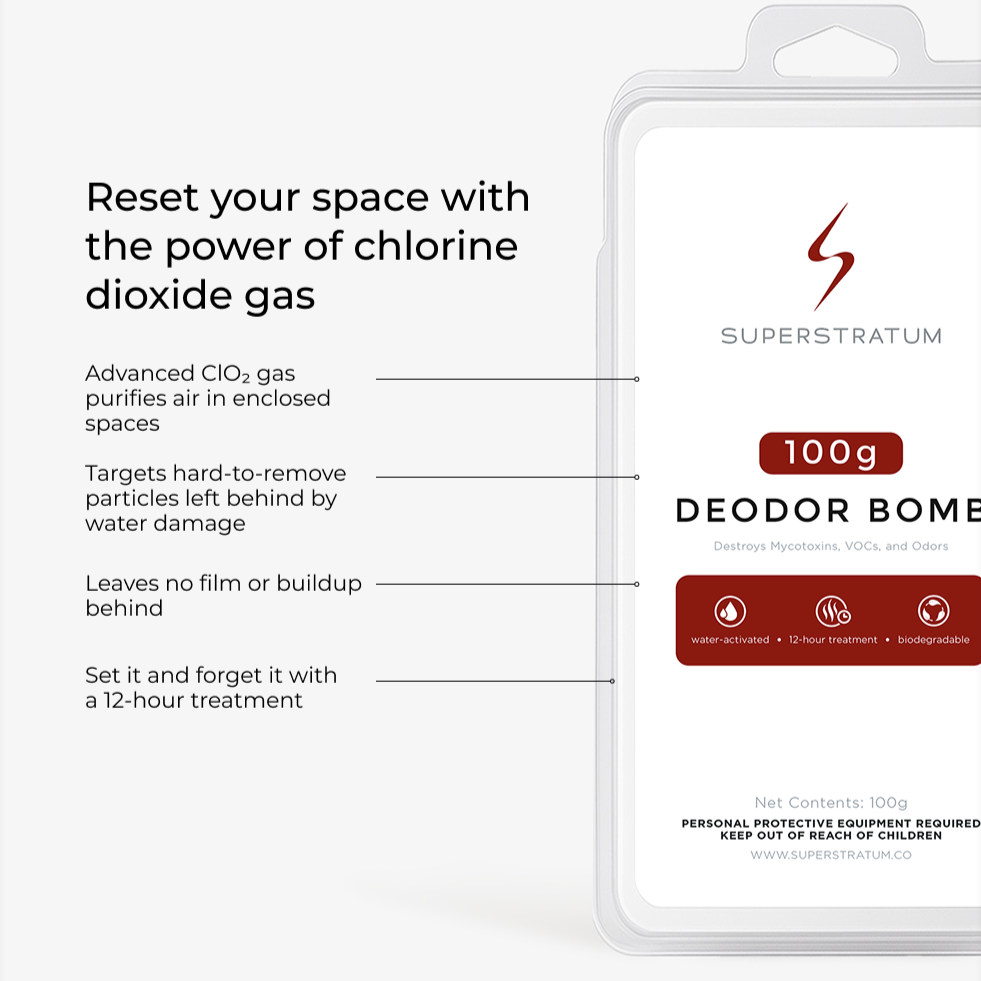

Phase 2: Gas

USE FOR

- Deodorization and decontamination of living spaces (Deodor Bomb) and non-living spaces (Deodor Bomb Pro)

- Indoor rooms, crawlspaces, attics, garages, sheds, automobiles, RVs

QUICK FACTS

- Generates chlorine dioxide (ClO2) gas

- Individually pre-packaged

- Biodegradable

- 12-hour overnight treatment

- People, pets, and plants must be removed from the home

- Destroys mycotoxins, VOCs and odors left by mold, mildew, urine, smoke, etc

Coverage Area

- 100G Deodor Bomb - 1000 cubic feet

- 50G Deodor Bomb - 500 cubic feet

- 25G Deodor Bomb - 250 cubic feet

- 100G Deodor Bomb Pro - 2000 cubic feet

- 50G Deodor Bomb Pro - 1000 cubic feet

- 25G Deodor Bomb Pro - 500 cubic feet

PPE

Not Required

Phase 3: COAT

USE FOR

- Hand spray bottle, garden sprayer, airless paint sprayer (411 tip)

- Lumber, drywall, grout, windows, HVAC systems, crawl spaces, indoor and outdoor furniture

QUICK FACTS

- Mold-resistant, invisible dry-film

- Resists mold 2 years outdoors; up to 10 years indoors

- Effective with a light coat

- Water-based chemistry

- Safe around people, pets, and plantsSafe on all surfaces

- Permeable to moisture

Whole Home Detox Knowledge Hub

Mycotoxin Removal Success Story – Cleaning and Restoring a 70-Year-Old Arlington Home to Health

There is still much to learn about the substances produced by mold, and even more about how to properly identify and remove them from indoor environments. Growing awareness around indoor air quality has brought significant attention in recent years to the emerging problem of mycotoxins in our living environments. New evidence is showing these poisonous compounds are present at alarmingly high levels in a substantial number of U.S. homes—they are undetected by conventional mold testing—and can persist even after visible mold has been removed. Addressing a sick home requires a solution that not only eliminates pathogens and microbes but more importantly denatures and destroys the molecular structure of a mycotoxin. The Client's Mycotoxin Challenge The client’s home was a 70-year-old property in a high-end neighborhood—clean, well-kept, and maintained. Despite the home’s good appearance, the couple’s daughter experienced chronic health issues they suspected were linked to the building. The homeowners had already carried out their own DIY remediation work, and through their efforts, they believed they had successfully removed the visible mold. However, their daughter’s symptoms persisted. This realization led them to search for a specialized solution—and ultimately brought them to SuperStratum Labs. Testing the Client's Home The Mold and Mycotoxin Detection Kit is designed to be a simple, affordable way for homeowners to determine whether mold and harmful mycotoxins are present in their environment. The kit can be used in two ways: 1. Direct Source Testing – Apply the mold tape directly to visible mold growth and use the mycotoxin swab on the same sample. This method identifies the mold species and shows whether it is actively producing mycotoxins. 2. Environmental Dust Testing – Collect samples from dusty surfaces such as door frames, bookshelves, or other areas where dust settles. Using both the mold tape and the mycotoxin swab in this way can reveal whether mold and mycotoxin contamination exist anywhere in the home—even if no mold growth is visible. Mold & Mycotoxin Detection Kit Unexplained health issues? Whether you suspect a hidden problem or are still feeling sick after mold removal, the cause could be invisible mycotoxins. Our advanced test, developed in partnership with Hayes Microbial, provides the clear, scientific data that standard tests miss. Order Your Test Kit The Procedure To begin our job, the Superstratum team wanted to determine whether there were signs of mold in the home and whether mycotoxins were present. This distinction is critical, as mycotoxins can persist in the environment long after the mold that produced them is gone. By only testing for mold, mycotoxins can be missed and remain in the environment, escaxerbating the chornic health conditions of occupants. Mold Spore Findings If these results were judged on mold presence alone, many homeowners, mold remediators, and even environmentalists might not consider them alarming. Additionally, the spore test told only part of the story—and not the part the homeowner needed most. It failed to explain why the family was feeling unwell, and it did not reveal the hidden dangers present in the home. The mycotoxin findings paint a very different picture. While spore counts may appear within an “acceptable” range, they do not measure the invisible, toxic compounds that mold can leave behind. In this case, the mold test underestimated the severity of the problem and missed what was actually making the family sick. Ascospores Spores from a large group of fungi, many of which grow on decaying organic matter. Some species are harmless, while others can be allergenic to sensitive individuals. Aspergillus/Penicillium Common indoor mold that thrives on damp building materials. Some species can produce harmful mycotoxins such as Ochratoxin A and Aflatoxin, and can also trigger allergies or respiratory issues. Myxomycetes Also known as slime molds; generally non-toxic and found in soil or decaying vegetation, but their spores can be allergenic to some people. Mycotoxin Findings The mycotoxin results confirmed the homeowner’s suspicion: even without alarming spore counts, dangerous mycotoxins were present at levels capable of causing adverse health effects, making a targeted mycotoxin removal plan essential. By most traditional inspection standards, these mold counts would not raise significant concern. However, low spore counts can be misleading—as the mycotoxin swab results revealed, toxic chemical residues can remain even after mold is no longer actively growing. Potential Health Risks for the Family Sterigmatocystin (STC) Produced by: Certain species of Aspergillus and Penicillium. Health impacts: Associated with liver and kidney damage, immunosuppression, and increased cancer risk. It causes DNA damage and oxidative stress, leading to mutations and tumor development in animal studies [4][5]. Stachybotrylactam Produced by: Stachybotrys chartarum (“black mold”). Health impacts: Stachybotrys toxins are linked to respiratory inflammation, immune dysfunction, and neurological effects. Animal studies show systemic health effects, and historical human cases associate S. chartarum with pulmonary hemorrhage in infants (though not conclusively proven) [9][10]. Inhalation Pathway of Mycotoxins to the Bloodstream and Brain Mycotoxins and ultrafine particles can also bypass the blood–brain barrier altogether by traveling directly from the nasal cavity into the brain through the olfactory and trigeminal nerves [1]. This dual pathway explains why exposure to mycotoxin-laden dust is associated not only with respiratory illness, but also with systemic, cognitive, and neurological effects. Click here. Hayes Microbial Consulting x Supertratum Labs A Partnership to Keep Families Safe Mycotoxin testing for homes is a new and developing science. Unlike basic mold spore tests, which often miss the root cause of illness, mycotoxin testing measures the toxic byproducts mold can release into the environment. Accuracy and sensitivity vary across the few available methods, and until recently, this type of testing was limited to professional and industrial use. At SuperStratum Labs, we partnered with Hayes Microbial Consulting to change that—developing the SuperStratum Mold & Mycotoxin Detection Kit to give homeowners direct access to clear, actionable results. Through this partnership, we’ve made liquid chromatography–mass spectrometry (LC-MS) testing—a gold-standard method typically reserved for the pharmaceutical industry and other highly specialized fields—accessible to homeowners. LC-MS is renowned for its unmatched precision, but until now, it has remained out of reach due to the high cost of equipment and ongoing laboratory upkeep. Hundreds of molds. Over 40 mycotoxins.The SuperStratum Mold & Mycotoxin Detection Kit is the industry-leading solution for homeowners, delivering the highest level of accuracy and the broadest range of detection available today. 👉 To learn more about why we chose LC-MS over other available methods, explore the lab behind the test here. Where do you begin when a home is sick? For many families living in a sick home, the situation is not always straightforward. It’s rarely just a matter of whether mold is present. Families often ask: Are mycotoxins still lingering even after mold remediation? How do HVAC systems contribute to spreading contamination? And in what sequence should all of these issues be addressed? What if I can't afford that? This is where our four-step structured framework becomes essential. The framework provides a way to understand how to use the Superstratum Whole-Home Detox in the broader context of a sick building—one that may involve water intrusion, visible mold growth, contaminated HVAC systems, and persistent health symptoms. The Whole-Home Detox itself is the final step of this framework—the part that specifically targets chemical mycotoxins, VOCs, and fine particulates that remain after traditional remediation. But its effectiveness comes from being applied at the right time, after moisture, mold, and air handling issues have already been addressed to the best of the homeowner’s ability. In the following section, we’ll show how our team applied this four-step framework in the Arlington case and why sequencing matters so much for achieving lasting results. Address the Moisture The basement and garage had a known history of water intrusion due to poor exterior drainage. The homeowner corrected the exterior drainage, stopping the ongoing moisture source feeding microbial growth. Address the Mold The homeowner performed a DIY mold treatment, removing visible contamination. While this addressed visible mold, it could not remove the microscopic residues and mycotoxins left behind. Address the Air To prevent spores and toxins from recirculating, the family hired an HVAC company to thoroughly clean the ductwork, eliminating any mold growth or contaminated dust. Detox the Home Even after visible mold removal and HVAC cleaning, harmful mycotoxins were present. We implemented the Superstratum Whole Home Detox to neutralize and physically remove them. Plan of Attack: The Whole-Home Detox We implemented the SuperStratum Whole-Home Detox, a process that pairs targeted HE-HOCl and CLO2 chemistry, scientifically proven to break apart mycotoxins at the molecular level, with a thorough small particle cleaning protocol. This three-phase approach first neutralizes the toxins so they are no longer dangerous, and then physically removes them from the home. By addressing both the chemical and physical side of contamination, we eliminated the hidden hazards that other remediation methods often leave behind. Download our Whole Home Detox manual for the full details instructions. Phase I – Cleaning Fogging the Home We began by fogging SuperStratum Building Cleaner into the environment. As the micro-fog settled, it knocked airborne dust and particulates out of circulation while breaking down mycotoxins clinging to surfaces and embedded in dust particles. This step actively neutralizes dangerous mycotoxins. Unlike mold fogging products that may kill mold spores but don’t break down mycotoxins, SuperStratum’s HE-HOCl is independently verified to break apart the molecular structure of mycotoxins, rendering them harmless before physical removal. Superstratum Whole Home System - Step 1 Superstratum Whole Home System - Step 2 The Small Particle Clean The Whole-Home Detox is not just a combination of cleaning products—it’s a mechanical process supported by chemistry that denatures mycotoxins. The most important phase is the mechanical wiping of inert dust after fogging, known as a small particle clean. Every surface in the home—walls, counters, trim, furniture—is wiped by hand using SuperStratum Building Cleaner and disposable wipes. Wipes are disposed of immediately to prevent recontamination. Belongings are wiped thoroughly, as mycotoxins often cling to surfaces like books, décor, electronics, and fabrics. Phase II – Gas Phase For this Arlington home, we deployed Superstratum Deodor Bombs in every room. These devices release a carefully measured dose of chlorine dioxide (ClO₂) gas, allowing it to penetrate deep into porous materials, hidden recesses, and micro-crevices that liquid sprays or fogs cannot reach. This phase was essential for oxidizing and breaking down residual mycotoxins, VOCs, and odor molecules trapped in fabrics, wall cavities, and other hard-to-reach reservoirs. Before releasing the gas, we raised the home’s relative humidity to around 70% for optimal ClO₂ effectiveness. The home was vacated overnight for 12 hours, then aired out. Superstratum Whole Home System - Step 5 - YouTube Why We Don’t Use or Recommend Ozone The U.S. Environmental Protection Agency (EPA) advises against the use of ozone generators for indoor air cleaning. The EPA also warns that ozone reacts with indoor materials to form secondary pollutants such as formaldehyde, adding further respiratory risks [11]. In addition, ozone generators can create nitrogen oxides (NO and NO₂) as by-products, which are themselves harmful respiratory irritants [12]. For these reasons, ozone is not recommended for mold or air cleaning. Phase III - Coating A 10-Year Mold-Resistant Coating The final step was the application of SuperStratum Endurance Coating to high-moisture-risk surfaces throughout the home. Unlike many mold-resistant coatings that rely on encapsulation, Endurance Coating is invisible, permeable, and breathable. It allows treated surfaces to maintain their natural vapor permeability while resisting mold growth. It bonds at a microscopic level, delivering long-lasting performance without trapping moisture or altering the look of the surface. By applying Endurance Coating in targeted areas, we provided an extra layer of performance against future microbial growth. Every Job is Different No two homes are alike, and no two detox jobs are exactly the same. Each property has its own layout, history, and environmental conditions that require adjustments to the process. In this case, one key challenge was an unconditioned storage room directly adjacent to a conditioned basement. The temperature differential between the two spaces allowed moisture to condense on the shared wall inside the unconditioned storage room, creating ideal conditions for microbial growth and mycotoxin persistence. We addressed this in two key ways: Airflow & Humidity Control We instructed the homeowner to keep the door open, leveraging the basement's HVAC system for dehumidification and temperature equalization in the storage room. Mold-Resistant Coating We applied Superstratum Endurance Coating to all storage room surfaces, providing long-term a long term and invisible mold resistance. By combining building science adjustments with effective chemistry, we gave this space a much better chance of staying clean and safe. Post-Results When planning post-remediation verification, it’s important to understand how dust collection timing can affect results: If all dust is removed, post-testing only confirms no new contamination, not neutralization of existing toxins. To verify neutralization, we recommend leaving settled dust undisturbed for sampling, or waiting for natural dust re-collection before testing. After completing the SuperStratum Whole-Home Detox, follow-up LC-MS testing showed all previously detected mycotoxins were below detectable limits. In this Arlington home, we intentionally left dust in place on surfaces to ensure our testing could directly confirm that the original mycotoxin contamination had been denatured and rendered harmless. The LC-MS results following treatment validated this approach, showing a complete elimination of detectable Stachybotrylactam and Sterigmatocystin. Conclusion By combining sensitive LC-MS testing, HE-HOCl and CLO2 chemistry, mechanical small particle cleaning, and long-term mold-resistance, we transformed this home from a hidden health hazard into a safe, healthy environment—confirmed with scientific precision. And most importantly, the SuperStratum Whole-Home Detox is designed to be both effective and simple enough for homeowners to perform themselves. Our goal is to put professional-grade detoxification tools directly in your hands.If you’d like more information about our products or our professional service options, please contact us. The Superstratum Whole Home Detox Still feeling the effects of a sick home, even after remediation? The Whole Home Detox is our proven, patent-pending system to clear the lingering contaminants. Start Detoxification Today References [1] Springer. Toxicology of Inhaled Substances. “The respiratory tract is a primary portal of entry for toxins, with alveoli providing direct transfer into circulation.” Springer [2] MedicalXpress. “Inhaled toxic particles can cross the lung’s air–blood barrier, enter the bloodstream, and reach the brain.” MedicalXpress [3] International Agency for Research on Cancer (IARC). Monographs on the Evaluation of Carcinogenic Risks to Humans. Group 2B: Sterigmatocystin classified as a probable human carcinogen. IARC Monograph [4] HealthMatters. “Sterigmatocystin.” healthmatters.io [5] Sherlock Inspector. “Sterigmatocystin.” sherlockinspector.com [6] Viegas C, et al. (2018). “Sterigmatocystin in Indoor Environments.” Mycotoxin Research. tandfonline.com [7] Bloom E, et al. (2017). “Detection of Stachybotrys Mycotoxins in Indoor Dust.” Analytical and Bioanalytical Chemistry. Springer Link [8] PSE Community. “New Mycotoxins from Stachybotrys.” psecommunity.org [9] Pestka J, et al. (2008). “Toxicology of Stachybotrys chartarum.” Toxicological Sciences. Oxford Academic [10] Wikipedia. “Stachybotrys chartarum.” Wikipedia [11] U.S. Environmental Protection Agency (EPA). Ozone Generators that are Sold as Air Cleaners. Available at: https://www.epa.gov/indoor-air-quality-iaq/ozone-generators-are-sold-air-cleaners [12] California Air Resources Board (CARB). Ozone Generators Sold as Air Cleaners. Available at: https://ww2.arb.ca.gov/resources/fact-sheets/ozone-generators-sold-air-cleaners [13] Indoor Air Quality Science, Lawrence Berkeley National Laboratory (LBNL). Ozone and Indoor Chemistry. Available at: https://iaqscience.lbl.gov/ozone [14] U.S. Environmental Protection Agency (EPA). Technical Assistance Document for the Reporting of Daily Air Quality – the Air Quality Index (AQI). Notes on ozone reactions producing nitrogen oxides.

Learn moreThe Unsolved Problem of Mold-Resistant Coatings — Until Now

by Seth Jones Founder & CEO || Superstratum Labs Mold resistance is one of the toughest challenges in modern building science. Builders, architects, and environmental professionals all share a common frustration: how do we achieve mold-resistance in real-world, moisture-laden environments? The answer, until recently, has been: you can’t. Even seasoned mold remediation experts remain skeptical that any product can truly “resist” mold in the face of repeated wetting and drying. This skepticism isn’t misplaced. Historically, the chemistry and physics simply haven’t been there. In this article, we’ll explore why true mold resistance has been so difficult to achieve, and introduce the first solution to crack the code: Superstratum Endurance Coating (EC). We’ll examine its chemistry, the biological mechanisms it leverages, and laboratory test results demonstrating its performance in extreme conditions. Why Mold Resistance Has Seemed Impossible Let’s look deeper at why past attempts to create mold-resistant coatings have failed. The Fundamental Problem: Bioavailability of Biocides Biocides are substances capable of killing or inhibiting microorganisms, including mold. However, there’s a fundamental paradox in coatings: To be durable, a coating must cure into a solid film, sealing the surface beneath. Yet, once biocides are locked into this film, they’re no longer bioavailable [1]. In other words, the active agents that could stop mold growth become inaccessible because they’re physically trapped inside a hardened layer of resin or polymer. Shortcomings of Traditional Mold-Resistant Technologies Quaternary Ammonium Compounds (“Quats”) Quats are among the most common antimicrobial agents used in cleaners, disinfectants, and some protective coatings. They work by disrupting microbial cell membranes. However, quats are water-soluble. Moisture can wash them away. Their antimicrobial potency degrades rapidly when exposed to oxygen, UV light, or fluctuating humidity. Once a quat dries onto a surface, it may become chemically inert and lose efficacy. In laboratory tests, even highly concentrated quats failed to prevent mold regrowth under moisture exposure [5]. Encapsulating Paints and Coatings Mold-resistant paints often contain biocides mixed into the liquid formulation. When applied and dried, the biocides are locked within a continuous cured film. Mold spores cannot reach the biocides. The biocides cannot migrate to the surface without breaking the film. Thus, these coatings act more as physical barriers than active antimicrobial defenses. If moisture penetrates or condenses behind the film, mold may still grow underneath and cause structural fungal issues like dry rot. This physical “encapsulating” effect is why mold-resistant paints often fail under real-world conditions, especially in crawlspaces, joists, and structural wood. Mold’s Survival Advantage Mold is a highly adaptable organism. Under the right moisture conditions, spores germinate within hours. Hyphae (the threadlike filaments of mold) penetrate porous substrates like wood, drywall, and masonry. Mold colonies produce secondary metabolites called mycotoxins, which can chemically damage surrounding materials and harm human health [4]. Traditional coatings have simply not been engineered to outsmart mold’s biology. Superstratum Endurance Coating: A New Class of Chemistry Superstratum Endurance Coating (EC) represents a true breakthrough because it’s built around smart polymer chemistry—an entirely different approach to mold resistance. Water-Based, Yet Water-Resistant EC begins as a water-based liquid, making it safe and easy to apply to virtually any building material: Wood Concrete Masonry Vinyl Stone Metal Fabric Once applied, it dries into an invisible, breathable film. However, unlike paints, it does not form a single continuous barrier [1]. Smart Polymer Matrix Here’s where the technology gets innovative: The polymer system creates a microscopic speckled pattern. These speckles create a web matrix with each node encapsulating biocidal agents. Rather than forming one big solid layer, these nodes leave small gaps between them. These gaps serve two critical functions. They preserve the substrate’s breathability. They allow biocides to migrate to the surface under wet conditions [1]. Water Activates, Not Washes Away Conventional wisdom says that moisture destroys antimicrobial coatings but EC turns that paradigm upside down. In dry conditions, biocides remain encapsulated, minimizing unnecessary release. When exposed to moisture, the polymer changes slightly. This change shifts the biocides to the coating’s surface. Once moisture evaporates, the polymer shifts back, protecting the remaining biocides for future use [1]. In this sense, EC is a smart polymer: water triggers its protective action rather than destroying it. And all of this is happening at an invisible level. But what's in it? EC uses biocides commonly found in personal care products like shampoos, lotions, and baby wipes—not the industrial biocides typically used in cleaning or mold remediation products. These consumer-grade biocides are formulated for safety even with direct skin contact and are well studied in toxicology literature for their low hazard profiles at typical use levels [1]. Labs and Customers Putting Endurance Coating to the Test Laboratory testing provides the ultimate proof. Let’s explore three key experiments. Lab Test Case – Extreme water exposure In a straightforward yet revealing test, two squares of Whatman filter paper were sprayed with EC. One square was subjected to continuous running water for 24 hours. Both samples were then inoculated with mold spores and incubated for 3 weeks at 82°F. Results: Sample one showed a zone of inhibition around the coating demonstrating its extreme mold-resistance applied. Although sample two was exposed to continuous water for 24 hours, there was still no mold growth and the zone of inhibition remained intact. Mold Remediator Test Case – Quat Comparison on Mold Plates To benchmark EC’s performance against their traditional chemistry, a leading national mold remediation franchise conducted a comparison with quaternary ammonium compounds. Procedure: Petri dishes were sprayed with either Superstratum EC, a 6% solution of quaternary ammonium salt, or a 25% solution of quaternary ammonium salt. All samples were allowed to dry. The dishes were then inoculated with mold spores [5]. Day 3 Observations: Mold growth appeared in both dishes treated with quat solutions—even at 25% concentration. The EC-treated dish showed no mold growth. Day 15 Observations: Mold overran the dishes treated with quats. The EC dish remained completely mold-free. Final Results After Two Months: “Two months after inoculation, Superstratum Endurance Coating Pro still showed no signs of growth.” [5] The company's technical team co-presented these results to their national licensees in a webinar to highlight a critical point. Traditional quats cannot survive long-term moisture exposure and environmental challenges. EC’s polymer matrix preserves biocide activity, delivering reliable mold-resistance over weeks and months—not just days. Duct Cleaning Test Case – Testing on HVAC Treated Liner An additional independent test conducted by a leading duct cleaning company in Dubai evaluated Superstratum Endurance Coating Pro on a treated liner using ASTM D 3273-21, the standard test for resistance to mold growth on coatings in environmental chambers [6]. Procedure: Two samples were tested: A liner treated with Superstratum Endurance Coating Pro An untreated liner as a control Samples were placed in a controlled environmental chamber and exposed to mold spores of: Aspergillus niger Aureobasidium pullulans Penicillium species The exposure lasted 4 weeks under elevated humidity and temperature, with weekly visual inspections. Results: The untreated liner deteriorated steadily, dropping to a rating of “6” by week four, indicating 31–40% mold coverage [6]. The treated liner consistently scored “10” on the ASTM scale, indicating zero visible mold growth or defacement throughout all 4 weeks. Applications in Building and Construction For professionals in architecture, building, and remediation, EC offers applications throughout the construction lifecycle. HVAC Systems EC can be applied directly to cooling coils, HVAC duct interiors, and return air plenums [2]. Crawlspaces EC can be sprayed onto joists, subfloors, and insulation surfaces. It’s effective either as a standalone treatment or as an added layer over encapsulation systems [2]. Building Materials During Construction EC is a proactive defense during new builds. Spray untreated lumber and OSB as it arrives on-site to coat materials before they’re enclosed in walls. Apply during framing to all structural members exposed to weather during construction delays [2]. Exteriors EC can be applied to exterior surfaces subject to persistent shade, splash-back from rain, and humidity exposure. Common targets include siding, patios, shaded north walls, outdoor furniture, and stonework. A long-term field test demonstrated no mold growth even after 20 months of exposure [5]. How to Apply Endurance Coating Application is straightforward, even in the field. A variety of spray equipment can be used. A light mist is all that’s required. No wiping necessary [2]. Handheld spray bottle Garden pump sprayer Airless sprayer (use 411 or 211 tip for fine mist) Coverage: Professional applications: ~600 sq. ft. per gallon. For lighter protective uses: up to ~800 sq. ft. per gallon [2]. Safety Precautions: Wear a basic mask (N95) if spraying in enclosed spaces to avoid inhaling aerosol droplets. No special ventilation is required for open-area applications [1]. Using EC in New Construction Forward-thinking builders can integrate EC into multiple stages. Phase I: Material Arrival – Spray lumber, trusses, and OSB immediately upon arrival to protect against weather exposure before dry-in [2]. Phase II: Framing Stage – Apply EC to wall framing, roof decking, and floor joists. This protects structural members even if the building is exposed to rain delays [2]. Phase III: Crawlspace Treatment – Spray subfloor undersides, vapor barriers, and crawlspace framing before insulation or encapsulation systems are installed [2]. Phase IV: Dry-In and Finishing – Once the structure is weather-tight, spray exterior walls, plumbing drops, subfloors, and optionally drywall surfaces in high-humidity areas [2]. Safety Profile of Endurance Coating No matter how effective a product is, it must be safe for both occupants and construction workers. Key Safety Attributes: EC contains no per- or polyfluoroalkyl substances (PFAS) [1]. The water-based formulation emits minimal volatile organic compounds during application [1]. After curing, EC is an inert, breathable, invisible polymer. It does not release vapors into indoor air [1]. Ingredients used in EC are common in personal care products like lotions and shampoos, at concentrations far below hazardous levels [1]. Once cured, EC presents no inhalable dust or particulates. CTEH’s toxicological evaluation concluded that even inhalation during application is far below levels of concern [1]. Unlike many mold treatments that rely on industrial quaternary ammonium compounds or harsh fungicides, EC’s active ingredients come from industries where stringent human safety standards apply, such as cosmetics and household products. This sets EC apart in the mold remediation world, offering effective protection without relying on chemicals that can become inert or lose efficacy under repeated moisture exposure. Because these biocides are incorporated into EC’s proprietary smart polymer system and used at very low concentrations, their individual levels are below reportable thresholds on Safety Data Sheets (SDS) and do not appear as discrete listings in public technical documentation. However, to ensure full safety and transparency, CTEH performed a rigorous third-party toxicological review of EC’s complete formulation, examining both publicly available historical toxicology data and proprietary data provided by the raw material suppliers. Their assessment confirmed that all active ingredients and other constituents in EC are used at levels far below those associated with health risks under normal and foreseeable conditions of use [1]. 🔬 Take a Deep Dive: Endurance Coating Pro Superstratum Endurance Coating Pro isn’t just another invisible “mold paint.” It’s the first coating designed to work with water, not against it — delivering smart, moisture-activated protection that outperforms conventional quats and mold-resistant paints. From HVAC systems to crawlspaces, exteriors to structural framing, it’s an innovation built for the realities of construction, weather, and building science. ✅ Smart polymer technology✅ Survives hundreds of wet/dry cycles✅ Safe ingredients — no PFAS, low VOCs✅ Long-term mold resistance, even in extreme moisture✅ Proven lab tests against traditional biocides 👉 Want the technical data, application guides, or test case studies? Check out the resources or contact the Superstratum team for in-depth support. 🛒 Shop: Endurance Coating Pro Ready to integrate true mold resistance into your next project? 👉 Shop Endurance Coating Pro Equip your builds with the smart polymer technology that’s reimagining mold-resistant coatings for modern construction. 📚 Appendix: References [1] CTEH, Product Safety Evaluation: Superstratum Endurance Pro R-103. December 16, 2022.[2] Superstratum, Whole Home System Manual. Version 10-25-24.[3] Superstratum, Deodor Bomb Instructions. Version 07-25-24.[4] Superstratum, Mycotoxin White Paper. Version 07-25-24.[5] Superstratum, Endurance Coating Pro Test Case Studies. Version 8-22-24.[6] The Healthy Home Cleaning LLC, Liner Test Report WD-R-241018-0242/B. November 23, 2024.

Learn moreChlorine Dioxide Explained: Why ClO₂ Is the Smartest Choice for Safe, Effective Home Detox

Chlorine dioxide powerfully breaks down mycotoxins and VOCs where other cleaners fail. Superstratum Deodor Bombs use advanced technology to safely and efficiently release ClO₂ gas, offering homeowners an effective, eco-friendly solution for whole-home detox and better indoor air quality.

Learn more